-

Titanox

Creation date: 5th of November. 2012

Products

Titanox Industrie has asserted itself on the industrial technical fastenings market through its policy of product quality and technical superiority, its extensive roll-out, rapid stock turnaround and respect of delivery times. The range offered by Titanox includes the following technical fastenings and assembly systems : a wide range of PEM fasteners comprising studs, nuts, standoffs and captive screws. An easy, accurate and efficient mounting solution. manual or automatic welding generators for capacitor discharge welding, ARC welding or short-cycle ARC welding. These sturdy generators are ideal for welding studs, bushes, nails and nuts in the most aggressive environments. standard multi-grip, sealing, peel and triform blind rivets for quick and easy fixing, structural rivets for assemblies subject to strong tensile strength and shear stresses, and speed rivets on one-way needles for enhanced efficiency. floating nuts, blind nuts, inserts for plastic materials, neoprene, EPDM and nylon inserts, telescopic slides or ¼-turn fasteners. Choice is backed up by a wide selection of assembly tools: pneumatic and oil-pneumatic riveting and fastening machines and manually- or automatically-fed fastener installation equipment. Titanox covers a wide and varied sector of activities such as the automotive industry, electrical manufacturing, electronics, medical activities, the household appliance industry, telecommunications, IT and aeronautics.

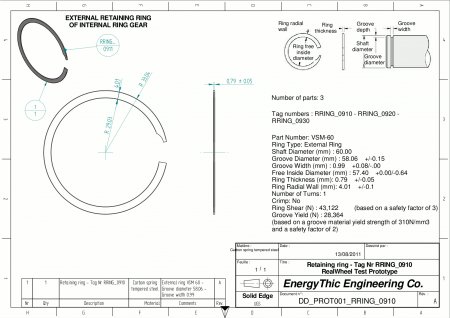

Titanox has participated to sponsorship of RealWheel motor

prototype and supplied the Smalley retaining rings in December 2011Wave springs, retaining springs "Smalley"

Smalley Wave Springs offer the unique advantage of space savings when used to replace coil springs. With a smaller assembly size and less material used in the manufacturing process, a cost savings is realized. Spirolox Retaining Rings have no ears to interfere® with mating components. Unlike die-stamped circlips Smalley® Retaining Rings are coiled on edge to the exact diameter required.

See manufacturer's website : wave springs, retaining springs

Other products

- Technical fasteners (self clinching, studwelding, riveting),

- Other fasteners (inserts for plastic materials, welding nuts, cage nuts),

- Ball bearing slides,

- Quick couplings,

- Latches, hinges, acess solutions

See manufacturer's website : other products

Services

Technical back-up

Titanox’s policy is to support its customers from the initial product stage onwards. We can collaborate with our customer’s engineering department and during the prescriber stage to offer specialised technical assistance and expertise built up over many years of experience in the field. Our aim: helping you choose the most suitable assembly solution. Our product managers provide information on the specifications of items featured in our catalogue, seek out and tailor with you the best technical solution for your application. For all your plant investment projects, from PEMSERTER fastening systems, HBS welding machines or riveters, we assist you in defining your need, choosing the machine and ensuring after-sales maintenance. We organise showroom demonstrations of our machines which you can also try out* in hands-on trial situations. We ensure assembly, commissioning and on-site staff training. *(in accordance with prior conditions defined during sales negotiations).

See manufacturer's website : sales maintenance

Link to supplier's website

Click on logo

Contact

Phone numbers

Phone : +00 33 1 47 86 74 40

Fax : +00 33 1 47 86 74 59Postal address

TITANOX

Z.A. du Petit Nanterre

141 / 143, rue du 1er mai

92737 Nanterre Cedex

FranceEmail