-

2012.03.19 Alstom inaugurates the largest offshore wind turbine in the world

- 2019.10.23 Google vient de réussir un exploit quantique

- 2019.10.18 Allemagne: La charge de soutien aux énergies renouvelables électriques

- 2019.03.25 France crossed the course of "Gray Day"

- 2018.08.03 Creation of ethanol from spruce wood

- 2017.10.29 L'énergie Solaire Mobile

- 2016.02.06 Max Velocity Turbine

- 2015.05.15 Eliminer le frottement entre deux surfaces

- 2014.12.02 Hydroliennes : GDF Suez-Alstom et EDF-DCNS lauréats de l'appel d'offre

- 2014.10.29 Rossi Congratulates Carl-Oscar Gullström on Theoretical LENR Paper

- 2014.09.11 Fast, clean, green, cheap: Is this our hydrogen fuelled future?

- 2014.07.26 New splitting technique for producing hydrogen fuel

- 2014.03.07 Here is the room where the Internet was born

- 2014.03.06 Is Earth's infrared radiation a potential energy source ?

- 2014.03.04 Lockheed had struck a deal with Ocean Power Technologies

- 2013.11.27 Lenrs and the Future of Energy

- 2013.11.08 UE: huit métaux stratégiques sous risque de pénurie

- 2013.08.12 Elton Musk unveils the Hyperloop project

- 2013.05.21 Indication of anomalous heat energy production

- 2013.04.24 Free Energy launches first solar assisted air conditioning

- 2013.03.04 "Artificial leaf" makes fuel from sunlight

- 2012.12.27 De l'eau de mer pour chauffer des habitations

- 2012.11.19 La méthanisation prend de l'ampleur

- 2012.11.09 La fusion nucléaire dans un appartement

- 2012.10.31 Parabole solaire Dish Stirling

- 2012.10.07 Revolutionary New Solar Power Technology

- 2012.09.25 Fine particles in Europe exceed WHO values

- 2012.09.17 Physicists make discovery about temperature in convection

- 2012.08.28 1000 MW de solaire photovoltaïque au Chili

- 2012.08.28 L'Allemagne ajoute 15,2 MW photovoltaïque à son parc

- 2012.07.27 The Asian Tiger Moskito will bite you

- 2012.08.03 Death of Martin Fleischmann

- 2012.07.20 Siemens to offer 1.3 billion euros for Ansaldo Energia

- 2012.07.13 Site traffic

- 2012.07.04 Higgs boson announcement live

- 2012.06.17 EU Water and Power Ltd was born

- 2012.06.11 Micro-hydroélectricité au Kenya

- 2012.06.05 New fuel cell in line for European award

- 2012.05.04 Association CIEL announces his goal

- 2012.03.19 Alstom inaugurates the largest offshore wind turbine in the world

- 2012.03.19 Le premier parc solaire de Haute Loire inauguré

- 2012.03.13 Terres rares : offensive contre la Chine à l'OMC

- 2012.01.25 Centrifugal force and Free Energy

- 2012.01.17 Alstom et SSE Ren. vont développer l'énergie de la houle

- 2011.12.30 Et pourquoi pas des éoliennes volantes

- 2011.11.07 Alstom projette de construire des éoliennes offshore

- 2011.09.11 L'ASN a reçu les rapports préliminaires ECS des exploitants

- 2011.07.01 Centrale hydroélectrique de pompage turbinage

- 2011.03.31 Nucléaire : les Agences de Sureté nationales et internationales

- 2011.03.17 Une nouvelle usine marémotrice en Ecosse

- 2011.01.19 Projet éolien offshore Français

- 2010.04.10 Un moteur surunitaire est en service en France

- 2010.11.18 Un complexe énergétique solaire géant à Ouarzazate

- 2010.09.27 Alstom s'affirme comme fournisseur leader du programme nucléaire chinois

- 2010.09.07 Alstom signe un contrat éolien au Royaume Uni

- 2010.06.12 Quelle électricité renouvelable en France ?

- 2010.05.20 Alstom fait son entrée sur le marché de l'énergie solaire

- 2010.05.17 Une vague géante fait couler la centrale de production d'énergie

- 2010.04.12 Pollution par les PCB

- 2010.03.24 Bill Gates promeut le nucléaire pour les pauvres

- 2010.03.23 La photosynthèse artificielle pour produire de l'énergie

- 2010.02.28 EDF investit dans une centrale solaire géante à Toul

- 2010.01.13 STEORN prouve la surunité

- 2010.02.10 Nouvelle centrale photovoltaïque en PACA

- 2010.01.04 La plus haute tour du monde inaugurée

- 2009.12.07 Un nouveau moteur brésilien surunitaire?

- 2009.11.13 Focus : Copenhague 2009

- 2009.11.04 Alstom et Schlumberger collaborent sur la techologie CO²

- 2009.11.04 Le débat sur le pic pétrolier serait inutile

- 2009.11.12 Solaire Citoyen

- 2009.09.21 Chine: 300 GW d'énergie électrique en 2020

- 2009.09.18 Rassemblement européen à Colmar

- 2009.09.09 Accident grave sur une barrage en Sibérie

- 2009.07.23 Les piles à combustible

- 2008.10.17 EDF choisit OpenHydro pour des hydroliennes

- 2008.09.08 - Le solaire photovoltaïque

- 2007.04.03 Une centrale solaire à tour en Espagne

- 2007.10.22 La production d'énergie pourrait décliner avant 2040

- Edition

-

2012.03.19 Alstom inaugurates the largest offshore wind turbine in the world

Alstom inaugurates the largest offshore wind turbine in the world, near Saint-Nazaire

On 19 March, Alstom inaugurated the largest offshore wind turbine in the world, at Carnet in the Loire-Atlantique. The ceremony was attended by Eric Besson, Minister of Industry, Energy and the Digital Economy, and Patrick Kron, Chairman and CEO of Alstom.

6 MW Haliade 150 wind turbine

Photographie publiée sur notre site avec l’aimable autorisation d’Alstom, reproduction interdite.

Photograph published on our site with courtesy of Alstom, reproduction prohibited.The 6 MW Haliade 150 wind turbine has been developed in response to a call for tenders launched by the French government in July 2011 that aims to install 3 GW of wind turbine power off French shores by 2015. In preparation for its certification, the first Haliade 150 will undergo a series of year-long tests on land at the Carnet site, before a second turbine is placed in the sea off the Belgian coast in autumn 2012. Pre-series production is planned for 2013 with production in series due to start in 2014.

The Carnet site, located near Saint-Nazaire on the shores of the estuary, was chosen for its geological characteristics that are very similar to the submarine environment in which the wind turbines will eventually be installed. The 25 metre sub-structure (known as the jacket) was installed on pillars driven more than 30 metres into the ground on which the 75 metre high tower was then gradually mounted. The nacelle soars over the landscape 100 metres above the ground. The wind turbine and its support structure have a total combined weight of 1,500 tons.

Read the Press Release on Alstom website

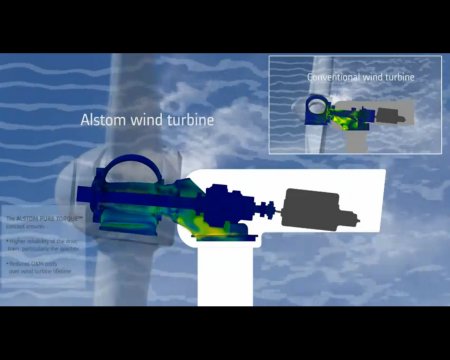

Technical comments: The Haliade turbine is equiped with Alstom Pure Torque © device.

Wind turbulence, wakes, etc, produce uneven load distribution on the rotor. Wind turbine must handle bending loads to protect the drive train.

In conventional wind turbines, the rotor is supported by the shaft bearing gearbox assembly. Bending loads are partially transmitted to the gearbox and may cause gearbox failures.

With Alstom Pure torque© device :

- The rotor is supported by a cast frame running through the hub,

- Bending loads are transferred directly to the tower,

- Torque is transmitted to the shaft through an elastic coupling at the front of the hub

The concept ensures:

- A higher reliability of drive train, particularly the gearbox,

- Reduced operating and maintenance costs over wind turbine lifetime.

On pillars over 30 feet deep, put up a structure of 25 meters with 75 meter high tower. Haliade 150 has the total weight, including both the structure and the turbine, of 1,500 tons.